Machine Tending

Kinemetrix robotic machine tending solutions help you to compete:

- Quick changeover for low volume/high mix production

- Fully integrated systems for unattended multiple shift production

- Keep your key process outputs protected from human variation and short-staffing

- A wide range of inline inspection techniques to confirm 100% part and process quality

- Integration of upstream and downstream processes such as: cleaning, assembly, and functional testing

FLEXIBILITY

Anticipating future production changes is challenging. Kinemetrix robotic machine tending solutions are designed with flexibility in mind:

Anticipating future production changes is challenging. Kinemetrix robotic machine tending solutions are designed with flexibility in mind:

- Rapid, tool-less, or completely automated changeovers. Run low volume/high mix production profitably.

- Scalable systems expandable as production volumes increase

- Modular robotic machine tending units on mobile docking bases allow reconfiguration of layout and production flow.

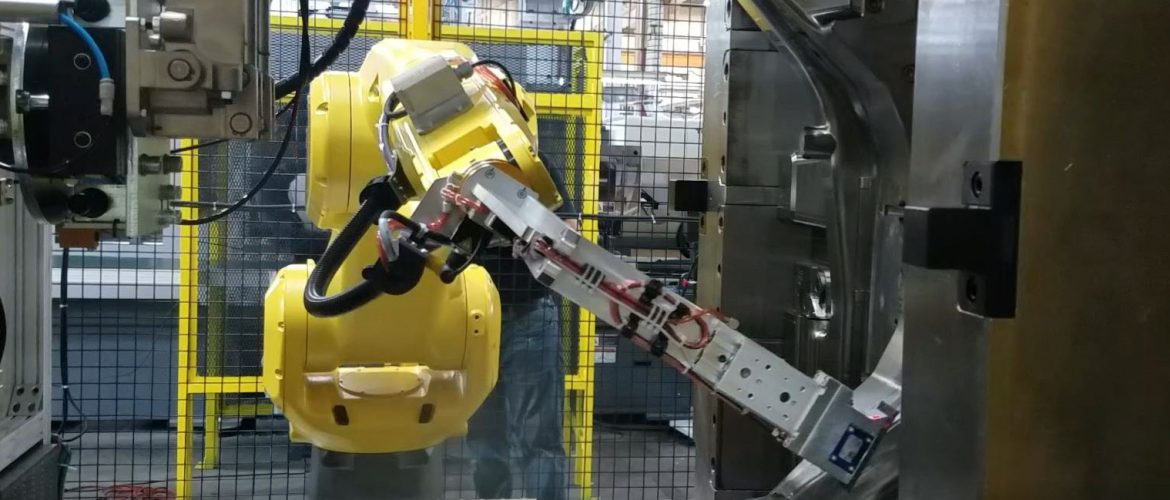

- Machine tending solutions tailored to your application with floor-mounted, collaborative or overhead rail-mounted Fanuc robots.

SMALL PARTS PRESENTATION

Simple Feeding:

Simple Feeding:

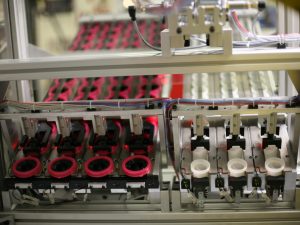

Standard small parts presentation methods can be deployed including:

- Vibratory Bowls & Tracks

- Tray Feeders

- Step Feeders

- Brush Feeders

- Centrifugal Feeders

- Chutes

Custom Feeding:

Successful automated machine tending results come from reliable part feeding, and skillful system integration. That’s it. Agile feeding solutions utilizing robots, machine vision and innovative mechanical design handle your range of production coponents. Find out more here.

Robotic bin picking reduces material handling costs by allowing robots to pick parts directly from totes and bins. 3D vision and sophisticated path planning are used to guide the robot. Find out more here.

LARGE PARTS PRESENTATION

Kinemetrix can design and integrate different methods to present large parts to your machines including:

Kinemetrix can design and integrate different methods to present large parts to your machines including:

- Conveyors

- Positioners

- Shuttles

- Pallet Feeders

PART MARKING AND TRACKING

Our machine tending systems tracks your parts and using serial numbers and lot codes via technologies such as:

Our machine tending systems tracks your parts and using serial numbers and lot codes via technologies such as:

- Laser Marking

- Pin Stamping

- Inkjet Printing

- Print and Apply Labeling

- Production database / MRP integration

INSPECTION & TEST

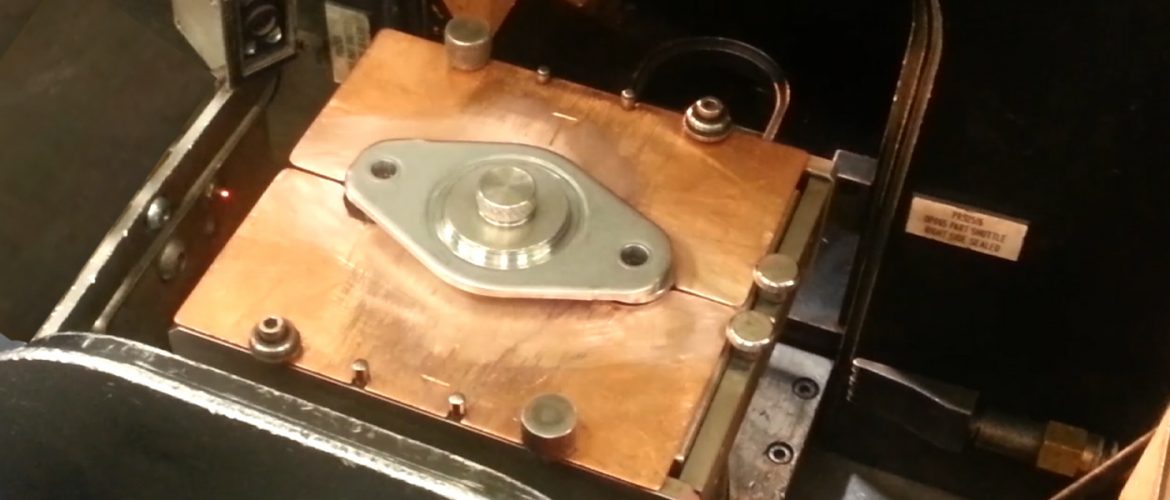

Automated in-process inspection is necessary to confirm quality before passing parts to the next operation. Parts are inspected before and after each process step for extremely high reliability output. Kinemetrix has experience developing all types of inspection and test solutions. Find out more here about the variety of automated inspections that are available.

Automated in-process inspection is necessary to confirm quality before passing parts to the next operation. Parts are inspected before and after each process step for extremely high reliability output. Kinemetrix has experience developing all types of inspection and test solutions. Find out more here about the variety of automated inspections that are available.

PART OUTFEED

Custom part outfeeds can be designed and integrated including:

Custom part outfeeds can be designed and integrated including:

- Conveyors

- Part Storage Racks

- Packaging Lines

- Robotic Palletizing Systems

- Dunnage Handling

Robots equipped with twin end-of-arm-tools can pass parts from one operation to the next efficiently, minimizing floorspace and hardware costs.