Research & Development

Manufacturers come to Kinemetrix to solve the toughest challenges in their plants. The solutions to these problems are not found in a catalog. Kinemetrix has developed mature processes to bring technologies from the laboratory onto the factory floor.

In addition to a large dedicated laboratory space, Kinemetrix devotes a significant portion of our engineering labor budget to R&D. Areas of R&D activity include:

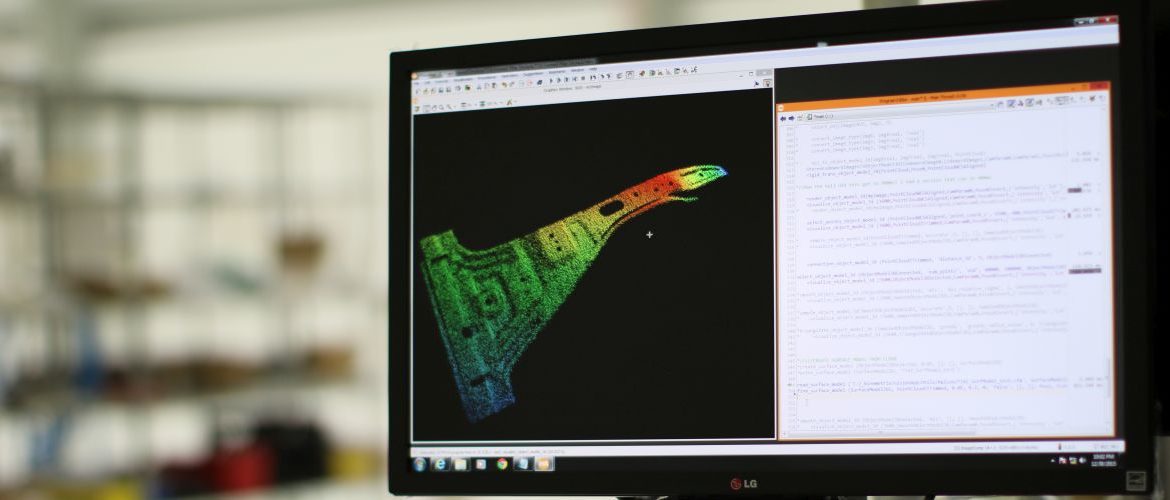

- Machine Vision Hardware & Software

- Special Mechanisms

- Leak & Flow Testing

- Board-level Electronics Solutions

- Software Tools

- Advanced Machining Methods

Where Science and Engineering Meet

Kinemetrix fosters a culture of continuous discovery. Our engineers stay current with research publications and the work of academic laboratories so they can act as a bridge between science and engineering. Capturing the advantages of new discoveries and delivering them to the manufacturing setting requires development effort. Our engineers keep one foot in a lab and the other foot in the reality of your plant floor when leveraging new technologies.

Kinemetrix fosters a culture of continuous discovery. Our engineers stay current with research publications and the work of academic laboratories so they can act as a bridge between science and engineering. Capturing the advantages of new discoveries and delivering them to the manufacturing setting requires development effort. Our engineers keep one foot in a lab and the other foot in the reality of your plant floor when leveraging new technologies.

Rapid Prototyping

The tools and habits of R&D allow Kinemetrix to minimize risk when tackling difficult projects. The prototyping of high-risk mechanisms and processes is embedded into our engineering cycle. We can rapidly go from CAD to working prototype using our:

The tools and habits of R&D allow Kinemetrix to minimize risk when tackling difficult projects. The prototyping of high-risk mechanisms and processes is embedded into our engineering cycle. We can rapidly go from CAD to working prototype using our:

- 3D Printer

- Water Jet Cutter

- Laser Cutter

- CNC Press Brake

- CNC Wire Bender

- Machine Vision and Optics Lab

There are far fewer challenges to be solved at the end of the project if the risky elements have been tested in advance.