Packaging & E-commerce Automation

Media

FLEXIBLE & FAST TO MEET TODAY’S CHALLENGES

Customers expect orders to ship quickly, accurately and without product damage. You need to do it with minimal labor at high volumes.

Kinemetrix designs and builds machines that produce & validate complex products. We develop intelligent, flexible automation for non-standard applications that cannot be solved with cookie-cutter solutions.

We work closely with your packaging engineers to smooth the transition from manual to automated packaging. Flexibility is designed in to allow order customization and to future-proof your equipment against product changes.

Contact us to discuss how we can develop a system that exceeds your needs.

- End of line packaging & palletizing

- Food products

- Beverages

- Cosmetics

- Personal care items

- Tool kits

- Medical devices

- Logistics automation

- Order picking for e-commerce fulfillment

- Warehouse material movement using mobile robots

- Reverse logistics for processing returned items

- Depalletizing of incoming products

Picking

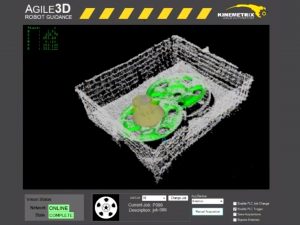

Our picking solutions maximize flexibility by using:

Our picking solutions maximize flexibility by using:

- 2D or 3D machine vision

- High-speed vision-guided robots

Using these tools, we can pick from:

- Moving conveyors

- Pallets

- Racks

- Bins & Totes

- Products delivered by Autonomous Mobile Robots (AMR)

We also supply & pick from traditional feeding mechanisms such as:

- Bowl feeders with vibratory tracks & hoppers

- Tray feeders

- Magazine feeders

- Fixtured, indexing conveyors

Part validation can be incorporated into the picking operations. Examples include:

For primary packaging applications in washdown environments, your system needs to be built to withstand caustic cleaning solutions and high-pressure spraying. To meet GMP requirements that ensure safety of your products, we apply sanitary design principles to engineer and select the proper equipment and materials, such as:

- Robots

- Conveyors

- Motors

- Inspection equipment

- Control panels

- Lubricants

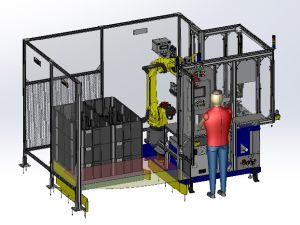

Packing & Kitting

Products picked can then be packed. Loading of a wide variety of packaging formats and machines is available:

- Cartoners (horizontally and vertically loaded). We can supply both product loading systems and carton magazine loaders

- Pouch form/fill/seal machines

- Blister pack machines

- Vacuum pack machines

- Shrink and flow wrapping machines

- Fixtures or totes on Autonomous Mobile Robots (AMR)

Kits and custom packages can be assembled using vision-guided robots, agile end-effectors and flexible feeding technologies. We can build systems to pack multiple items into trays, boxes, pouches, racks and other package styles. These systems can also create unique configurations of items in individual packages on an order-by-order basis.

Kits can be used to group parts to support just-in-time manufacturing in your plant or packaged for shipping to your customers. Machine vision systems and barcode readers verify the correct components have been packed.

Examples of kits that can be assembled include:

- Tool kits

- Medical supplies

- Cosmetics

- Automotive parts

- Personal care items

Kinemetrix will supply fully integrated case packing lines, including product and case handling devices like:

- Timing screws

- Package collators

- Layer formers

- Case erectors

- Tray formers

- Case squaring and flap control devices

- Case closing and sealing machines

Validation & Tracking

Kinemetrix will add the validation steps you need to measure, mark, label, verify and trace your product or package. Whether you need to verify that the correct tools are present in a kit or need to detect contamination inside a sealed package, we can provide the right technologies.

Kinemetrix will add the validation steps you need to measure, mark, label, verify and trace your product or package. Whether you need to verify that the correct tools are present in a kit or need to detect contamination inside a sealed package, we can provide the right technologies.

- Laser marking

- Print and apply labeling

- Machine vision systems (including machine learning for complex image analysis)

- Barcode reading

- Check weighing

- Metal detection

- X-ray inspection

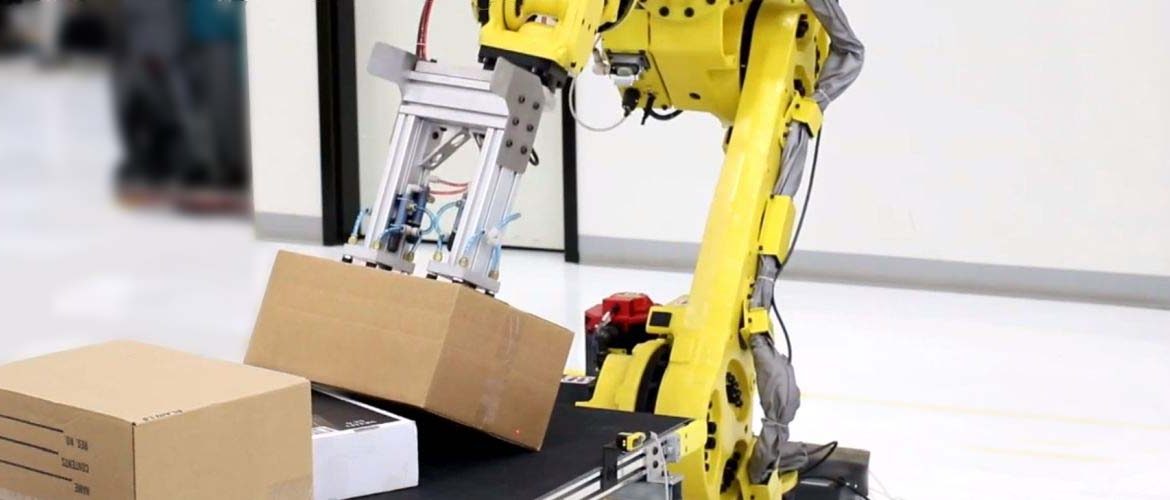

Palletizing

Kinemetrix provides a variety of palletizing and depalletizing solutions. Systems are custom engineered to your unit load and to fit in the space available in your factory. We can handle a wide range of parts and products:

- Corrugated cases

- Automotive wheels

- Sheet metal blanks

- Electronic modules

- Dunnage such as returnable trays, totes, dividers and layer sheets

We will finish the production line for you with unit load preparation equipment:

- Stretch wrappers

- Corner board applicators

- Labelers

- Banders