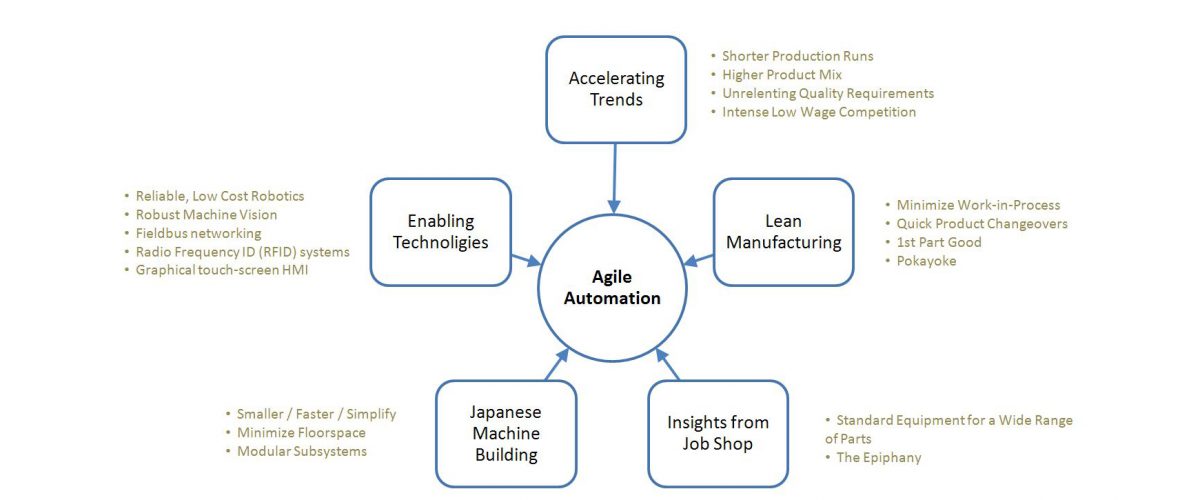

Agile Automation

Agile Automation handles two important tasks:

- Efficiently produce the products in your plan

- Adapt quickly when that plan changes

Agile Benefits

Plant-Floor Benefits

- Reduce Changeover Time

- Reduce WIP

- Free-up Floor Space

- Consistent Quality

- Flexible Capacity

Strategic Benefits

- Manage Risk

- Delay Obsolescence

- Reduce Product Launch Cost

- Win New Business

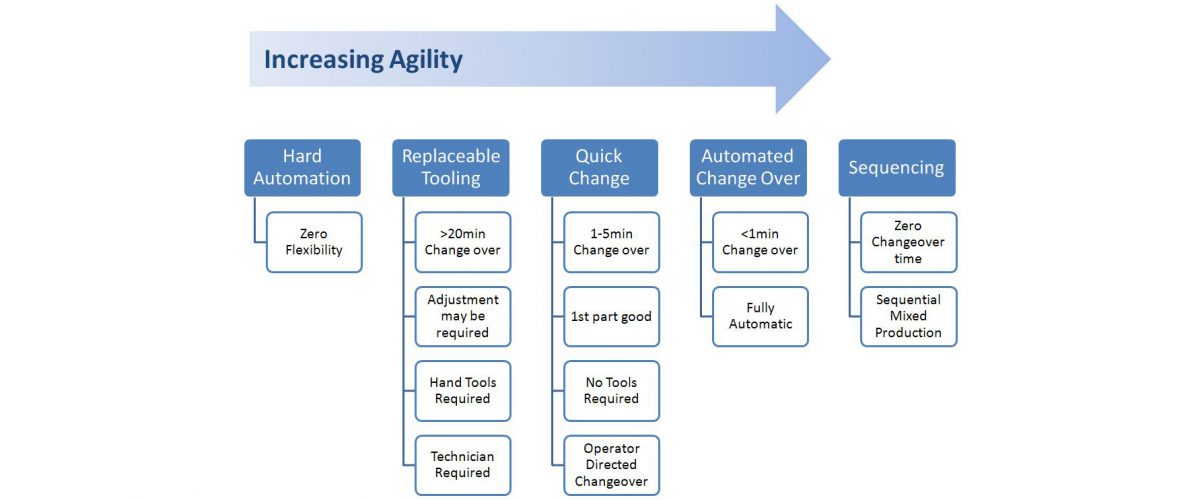

Reduce Product Changeover Time

By radically reducing or eliminating part-specific tooling, product changeover times are driven as close to zero as possible. This reduces direct labor costs and machine downtime.

Reduce Work-In-Process

More efficient changeover allows more frequent changeover without impacting throughput. Frequent product changeover allows you to produce in accordance with customer demand, rather than creating large batches. Reducing Work-In-Process (WIP) frees cash that would otherwise be tied up in inventory. This cash flow increase can be put to use more productively in your business.

Free-up Floor Space

One agile system can run a variety of parts that would require many traditional machines, and their associated floor space. Keeping old machines around to run service parts and short-runs is not necessary with Agile Automation. At the end of a product’s production cycle, simply store any part specific tooling (if applicable) rather than entire dedicated machines.

Those faster changeovers that reduce WIP also free-up floor space. Less storage is required.

Consistent Quality on Changeover

Stability is the goal of every manufacturing process. The first part of the shift – or after changeover – should be a sellable part with no rework required. By minimizing or eliminating human intervention during changeover, agile systems ensure consistent quality.

Flexible Capacity

When multiple Agile Automation systems are deployed for similar processes, the tooling is fully interchangeable across machines. It’s possible to run all machines on the same product or different product on every machine.

This offers tremendous flexibility to respond to wide swings in demand and comes at a fraction of the cost of multiple dedicated machines.

Manage Your Risks

Agile Automation gives you the ability to manage these risks. Think of any cost premium associated with agile features as inexpensive insurance against the risks of:

- Product design change

- Program cancellation or volume decrease

- Under-capacity or poor capacity balance

Delay Obsolescence

At the end of a product’s lifecycle, Agile Automation’s modular design lends itself to reconfiguration for new production demands. Whether the end of production comes according to plan or otherwise, agile systems have value that is not lost, hopelessly entangled in a part-specific design.

Reduced Product Launch Costs

Agile Automation allows you to launch new jobs with a small tooling investment as opposed to entirely new machinery. You quickly meet startup capacity requirements on existing Agile Automation. New machinery is added only as production increases. Agile Automation lends both a tooling cost savings and a capital investment savings for new business.

Win New Business

What story do you have to tell prospective customers? What differentiates your manufacturing capabilities? When you can demonstrate your manufacturing agility, they will take notice. With Agile Automation, your cost structure allows you to profitably produce the lower volume products that your competitors can’t touch. And because your tooling costs are minimal, simple, and well understood, you can respond quickly to customer pricing requests and compressed product launch schedules.