Assembly & Test

Media

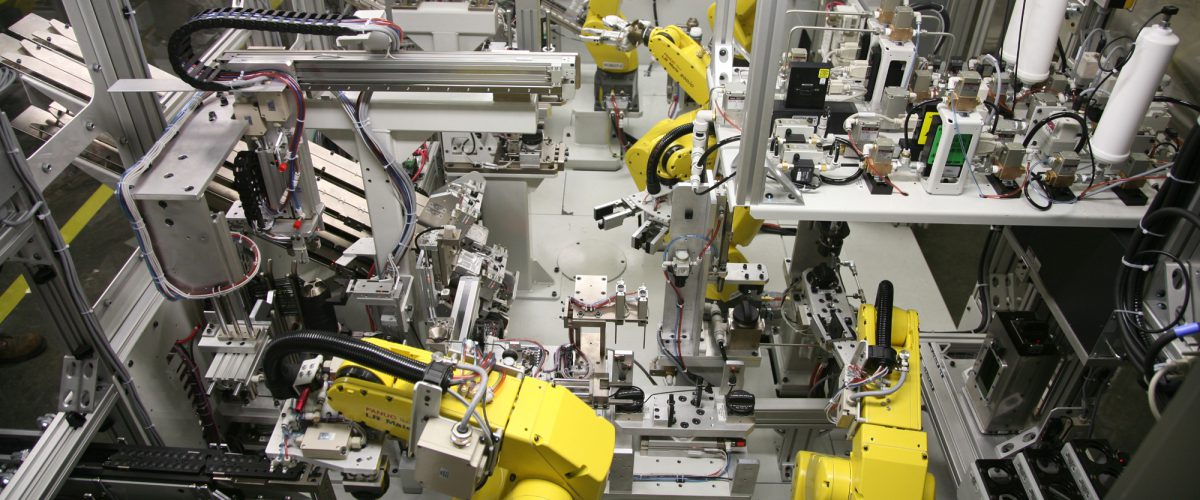

High speed assembly & test of complex products requires many different technologies. With Kinemetrix’s Agile Automation, you get:

- Flexibility to assemble a variety of product versions on the same line

- Minimal changeover time

- In-process inspection of each assembly step

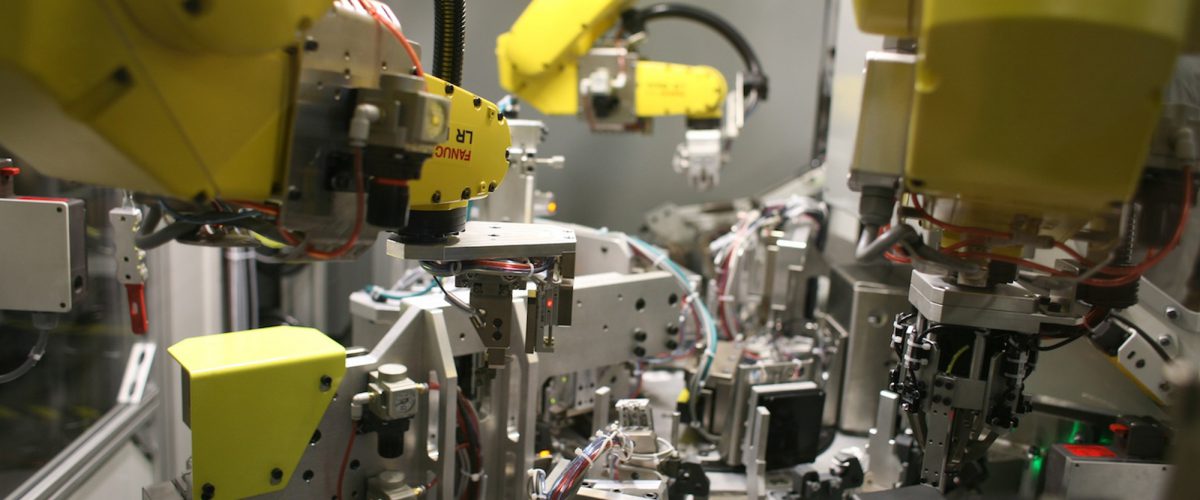

Joining Technologies

Assembling requires joining, and Kinemetrix can automate the ones that your product needs. Process monitoring can also be included to detect errors. Processes include:

Assembling requires joining, and Kinemetrix can automate the ones that your product needs. Process monitoring can also be included to detect errors. Processes include:

- Laser Welding

- Press and Snap Fit with Force and Displacement Monitoring

- Mechanical Fastening with Torque and Displacement Monitoring

- Deformation Fastening

- Clip Insertion

- Single Part Adhesives such as hot melt or RTV

- Two-Part Adhesives such as Urethane with temperature, humidity and ratio controls

- Ultrasonic welding

- Heat staking

Part Infeed

Parts to be assembled must first be presented to the automation. Kinemetrix uses traditional methods where appropriate. These include:

Parts to be assembled must first be presented to the automation. Kinemetrix uses traditional methods where appropriate. These include:

- Conveyors

- Pallets & Trays

- Vibratory Bowls & Tracks

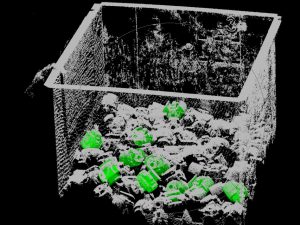

Agile Feeding can leverage your investment by allowing the automation to assemble a wide range of products. Robots, machine vision and clever mechanical design are used to handle a wide variety of parts. Find out more here.

Robotic Bin Picking can reduce material handling costs by allowing robots to pick parts directly from totes and bins. 3D vision and sophisticated path planning are used to guide the robot. Find out more here.

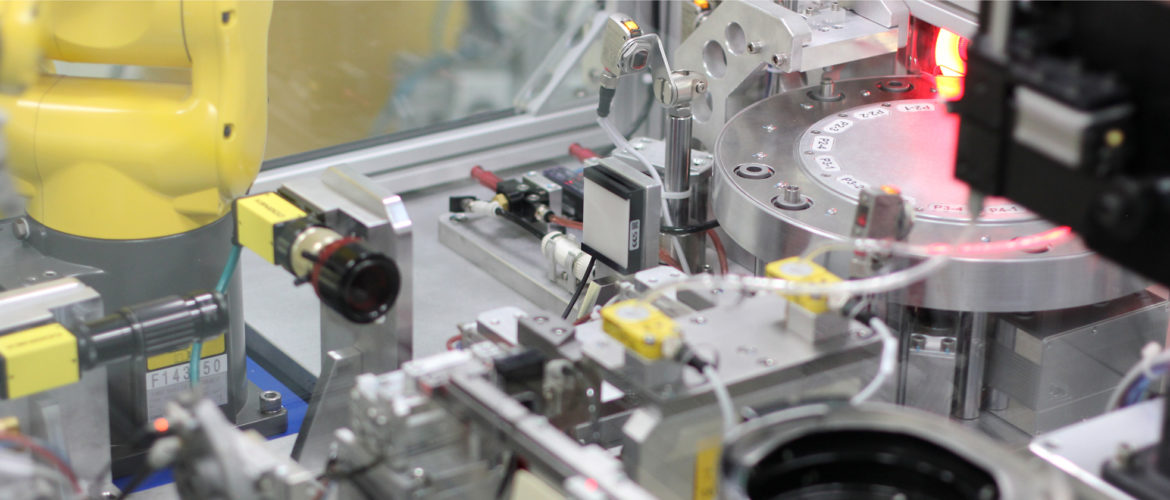

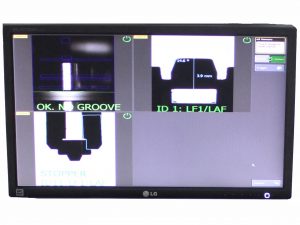

Component Inspection

Components are checked before assembly. This is critical when similar-but-different products are made at the same plant. If a component for Assembly A can be mistakenly installed into Assembly B, you need an inspection strategy to avoid hidden defects.

Components are checked before assembly. This is critical when similar-but-different products are made at the same plant. If a component for Assembly A can be mistakenly installed into Assembly B, you need an inspection strategy to avoid hidden defects.

Components are checked using poka yokes, machine vision, laser sensors, color sensors and other technologies to verify:

- Correct model

- Correct orientation

- Dimensions within specification

- All required features present (e.g. holes or threads present)

Testing

Complex assemblies require a variety of tests to ensure proper operation prior to shipment. Automated assembly systems perform automated testing based on your product requirements. This includes:

Complex assemblies require a variety of tests to ensure proper operation prior to shipment. Automated assembly systems perform automated testing based on your product requirements. This includes:

- Presence / Absence of Components

- Torque & Force Monitoring during assembly

- Functional Tests such as Range of Motion or Spring Force

- Flow Tests using Positive Pressure or Vacuum

- Pressure-Decay Leak Test

- Electrical Test

- Many others

Automatic Test Validation

Kinemetrix assembly & test systems are available with Automatic Test Validation. Parts that represent the boundary conditions of each test are stored in the cell. The automation is programmed to cycle these parts through the line on a schedule, or at the point of product changeover, to validate the performance of the inspection stations.

Kinemetrix assembly & test systems are available with Automatic Test Validation. Parts that represent the boundary conditions of each test are stored in the cell. The automation is programmed to cycle these parts through the line on a schedule, or at the point of product changeover, to validate the performance of the inspection stations.

Data Traceability

![]() A Kinemetrix assembly system will track the assembly process and build a data record to meet your requirements. This includes:

A Kinemetrix assembly system will track the assembly process and build a data record to meet your requirements. This includes:

- Assigning Serial Numbers

- Laser Part Marking

- Part Tracking to verify upstream operations are complete

- Process Data Collection at each step

- Communication of data records to your MES

Compact, Self-Contained Systems

Our assembly and test systems use very little floor space. The systems contain all the feeding, assembly and test operations on a single compact base. The system shown here contains the following functions in a package easily lifted and moved by a fork lift.

Our assembly and test systems use very little floor space. The systems contain all the feeding, assembly and test operations on a single compact base. The system shown here contains the following functions in a package easily lifted and moved by a fork lift.

- Feeders for 5 Individual Components

- Laser Welding

- Snap Assembly with Force Monitoring

- Pressure Testing

- Flow Testing

- Laser Marking

- Fume Extraction

- Automatic Test Validation

- Accumulating Outfeed Conveyor