Agile Feeding

The first step in an automated operation is the feeding of parts. Simple, mechanical feeding methods still have their place, but most automation today must deal with more complexity:

- Many part styles

- Small lot sizes

- Several changeovers per shift

- No tolerance for long changeovers

The solution is Agile Feeding.

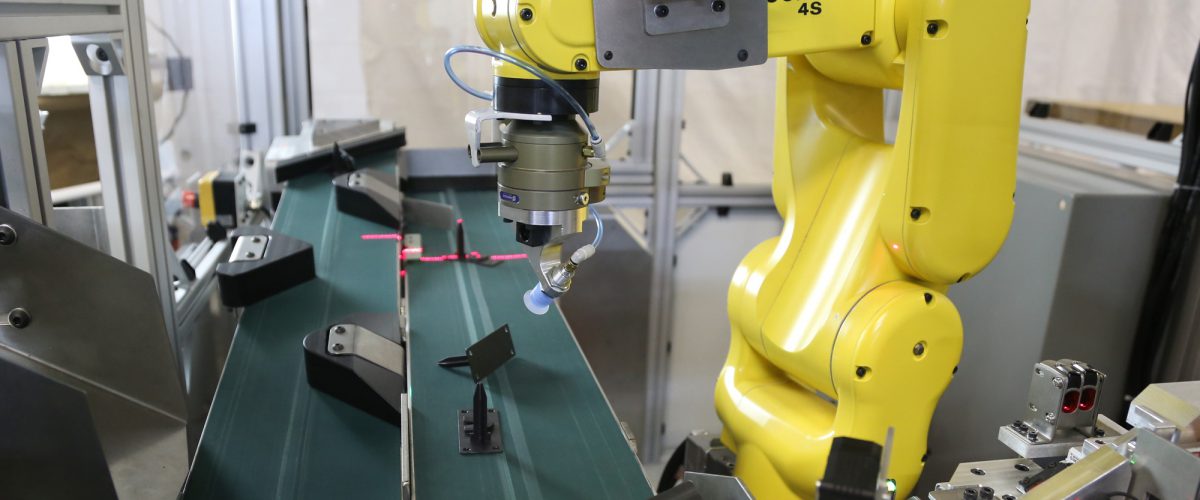

Agile Feeding uses a combination of generic mechanical feeding, vision and robots to create a system that can handle your part variety while providing high production rates.

Part Singulation

Bulk parts must be singulated and transported into the system. This is done using mixtures of hoppers, bowl feeders, conveyors, vibratory tracks, and other devices. The selection depends on the general size and characteristics of the part family.

Bulk parts must be singulated and transported into the system. This is done using mixtures of hoppers, bowl feeders, conveyors, vibratory tracks, and other devices. The selection depends on the general size and characteristics of the part family.

This step is similar to a traditional feeding method, but has an important distinction. Where a traditional system would singulate, orient and locate the part using part-specific hard tooling, the task here is limited to singulation. This allows the equipment to be generic and able to handle a family of parts with no changeover.

Part Location

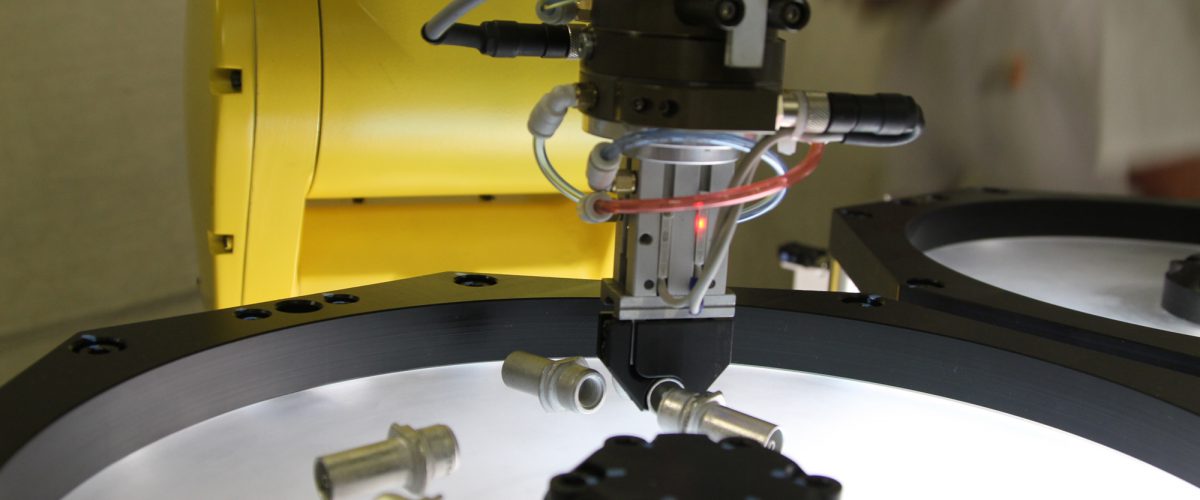

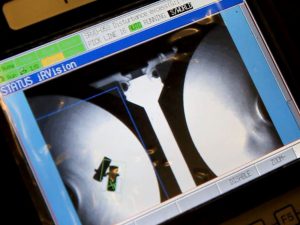

With Agile Feeding, the Part Location task is done with machine vision guiding the motion of a robot. Singulated parts are evaluated by the vision system to provide a pick location and orientation. The robot uses that information to get an accurate pick.

With Agile Feeding, the Part Location task is done with machine vision guiding the motion of a robot. Singulated parts are evaluated by the vision system to provide a pick location and orientation. The robot uses that information to get an accurate pick.

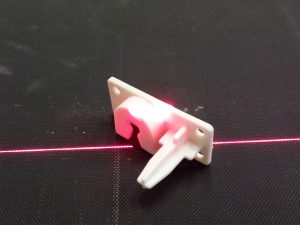

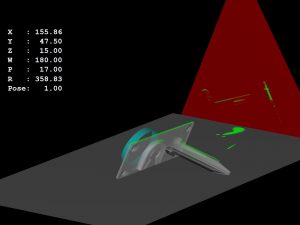

More Agile With 3D Vision

Three dimensional vision is our most powerful part location technology. Our system creates a 3D image of the part to be picked and matches it to the part data. This allows the system to identify and locate a part whether its face up, face down, or on its side. The robot is given part location and part orientation so that a picking vector can be chosen.

Three dimensional vision is our most powerful part location technology. Our system creates a 3D image of the part to be picked and matches it to the part data. This allows the system to identify and locate a part whether its face up, face down, or on its side. The robot is given part location and part orientation so that a picking vector can be chosen.