Freeform Blank Handling

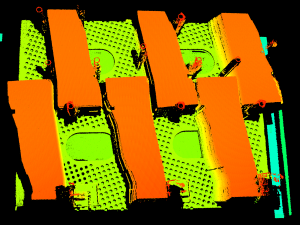

Pick blanks where they lie! Freeform Picking combines Kinemetrix Agile3D™ Robot Guidance and flexible end of arm tooling to pick steel blanks from stacks sitting on unregistered pallets. The Agile 3D Vision System used in this application is optimized for large area picking and is highly tolerant of variations in blank tilt, curve and surface finish.

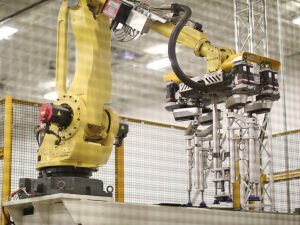

The AgileArm™ robotic tool automatically reconfigures to match part size and shape. System changeover to a new part is accomplished while the next pallet moves into position.

Key benefits of this system include:

- Anything-goes pallet handling accepts a wide variety of pallet types and stack configurations for both destacking and stacking

- High throughput while maintaining single-piece flow

- Double blank detection at the point of destack with automatic recovery

- Destacks 2-piece blanks that arrive in tilted stacks

Destacking with 3D Robot Guidance

Traditional blank feeding equipment runs great if you give it repeatable stacks. But it’s operationally expensive to create perfect stacks of blanks on dimensionally repeatable pallets with straight pins.

Traditional blank feeding equipment runs great if you give it repeatable stacks. But it’s operationally expensive to create perfect stacks of blanks on dimensionally repeatable pallets with straight pins.

What if you didn’t have to?

Kinemetrix Agile3D Robot Guidance can be configured to image large areas. In this application, the system finds stacks of blanks in a 2m x 2m space. The system provides:

- Verification of blank part number

- Number of stacks

- Location of each stack

- Height of each stack

The result is a complete removal of the usual constraints.

- Expensive precision pin pallets are no longer necessary

- Locating a stack precisely on a pallet is not needed

- No need to maintain identical stack heights on multi-stack operations

Anything-goes Pallet Handling

How are your blanks transported? Steel pin pallets? Wooden pallets? Wooden blocks? No problem. Set it on our pallet handling system.

How are your blanks transported? Steel pin pallets? Wooden pallets? Wooden blocks? No problem. Set it on our pallet handling system.

Blank stacks can be moved in and out on a shuttle or conveyor. It will:

- Allow blank stacks on any pallet type

- Carry one or multiple stacks

- Provide a mounting surface for fanner magnets

- Provide locations for support pins if needed

There is no need for precise location of the pallet or stack. The 3D vision system finds the stacks and guides the robot, making the system incredibly flexible.

Blank Stacking with 3D Vision

Kinemetrix Agile3D Robot Guidance also removes constraints for stacking blanks. Traditional systems need outgoing pallets to be precisely located so that stacks are placed accurately onto the pallet.

Kinemetrix Agile3D Robot Guidance also removes constraints for stacking blanks. Traditional systems need outgoing pallets to be precisely located so that stacks are placed accurately onto the pallet.

Let us show you how our 3D vision system creates straight, tight stacks on any pallet with no need to mechanically locate the pallet.

Agile Arms for Fast Changeover

The final constraint to be removed to achieve true agility is the robot gripper. Traditional systems require maintenance personnel to reposition cups on all robot grippers at changeover. This is time consuming and prone to error.

The final constraint to be removed to achieve true agility is the robot gripper. Traditional systems require maintenance personnel to reposition cups on all robot grippers at changeover. This is time consuming and prone to error.

Kinemetrix Agile Arms have cups located on servo-driven arms, allowing automatic repositioning of cups for different parts. The grippers, and therefore the entire system, are able to change over to the new part in the time it takes for a new pallet of parts to move into the system.

Consider the impact this would have on the daily throughput in your plant. You will wonder why you are still doing it the traditional way.

Safer for Team Members

Moving stacks into the system on a conveyor or shuttle separates team members from the robotic automation.

Moving stacks into the system on a conveyor or shuttle separates team members from the robotic automation.

Traditional robot destacking uses pallet locators that are within the robot reach. These locators must be loaded by a fork lift, requiring complex safety systems to keep team members safe during pallet load and unload.

Kinemetrix solution allows the forklift driver to unload & load pallets outside the robot perimeter.